In an unexpected twist that may sting for fossil fuel proponents, the Bipartisan Infrastructure Law (BIL) enacted in 2021 is now igniting the transition to renewable energy. One of the latest announcements from the U.S. Department of Energy reveals a $750 million investment from the BIL, specifically targeting the shift from traditional fossil-sourced hydrogen to sustainable green hydrogen derived from water.

Plug Power’s Role in Pioneering Green Hydrogen

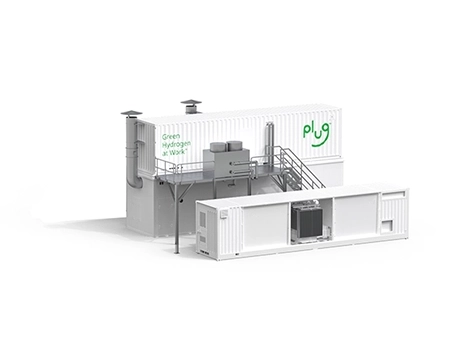

Notably, Plug Power, a leading green hydrogen startup, reached out to highlight this funding initiative. Having gained prominence for introducing fuel cell electric forklifts to minimize emissions at workplaces, they are still a key player in the industry. Unlike their battery counterparts, fuel cell systems offer logistical efficiency by saving valuable time and space.

Although fossil fuels once dominated hydrogen production, recent advancements in renewable energy and electrolysis technology have opened doors for greener alternatives. Given that hydrogen isn’t merely restricted to fuel cells but also vital across various sectors like food processing and pharmaceuticals, creating greener production methods is crucial.

Targeting Fossil Fuels with Green Hydrogen Strategy

Despite past struggles, Plug Power shifted its focus to manufacturing electrolysis systems that utilize renewable energy to extract hydrogen from water. As part of the BIL strategy, $1.5 billion has been designated for clean hydrogen projects, including advancements in electrolysis technologies.

It’s important to note that the term “clean hydrogen” has been contentious due to attempts by some stakeholders to include carbon-captured conventional hydrogen in this category. However, the Energy Department’s latest funding round prioritizes genuine green hydrogen produced from water.

Innovations in Electrolyzer Technology

Proton exchange membrane (PEM) technology currently dominates commercial electrolyzer markets, though it is costly. The Energy Department is focusing on reducing costs and moving towards more environmentally friendly materials, veering away from perfluorinated materials.

Plug Power is at the forefront of a grant project to replace such materials in PEM electrolyzers, and is engaging in efforts to automate the manufacturing processes to reduce costs and increase production efficiency of fuel cell stacks used in clean hydrogen technologies.

Alkaline Electrolyzers: An Emerging Alternative

While PEM electrolyzers are prevalent, there’s a budding interest in an older yet less expensive methodology – alkaline electrolysis. While more efficient on a larger scale, the purity levels of hydrogen produced are less than what PEM can provide. Plug Power’s involvement in a project with Ionomr suggests they’re aiming to address and improve upon the membrane technology used in alkaline systems.

A Holistic Approach to Green Hydrogen

Beyond just the production of green hydrogen, Plug Power and other institutions are looking into the full lifecycle, from supply chains and recycling to developing new, low-cost solutions for the entire green hydrogen economy.

While the BIL, and consequently the Department of Energy, cannot disregard natural gas altogether due to funding provisions, the recent focus on green hydrogen suggests a seismic shift toward renewable energy. The goal is set: by 2031, green hydrogen should cost just $1.00 per kilogram, potentially sidelining natural gas.